Les plaques de plafond en fibres minérales jouissent d'une grande préférence dans la plupart des bâtiments commerciaux et résidentiels grâce à leur excellente capacité d'absorption du son, leur résistance au feu et leur apparence élégante. La qualité de ces plaques peut varier, et il est crucial de savoir comment identifier des plaques de qualité pour garantir un rendement optimal et une durabilité maximale de votre installation de plafond. Les critères importants incluent la qualité de la plaque de laine minérale, la surface de la plaque de laine minérale, la forme de la plaque de laine minérale et les performances de la plaque de laine minérale.

La qualité de la plaque de laine minérale

La production de panneaux en laine minérale provient des matières premières et donc, un bon panneau en laine minérale doit utiliser de la laine minérale de bonne qualité. Le matériau principal pour fabriquer les plaques de plafond minérales est appelé laine minérale, il s'ensuit que la qualité de cette matière première est essentielle pour déterminer la performance et la durée de vie des plaques. Les plaques de laine minérale de bonne qualité sont généralement produites en combinant du basalte avec d'autres minerais et scories. Ces matériaux sont ensuite fondus sous forme liquide et des fibres sont créées à partir de leur processus de filage, puis elles sont liées par des matériaux adhésifs.

Les aspects suivants doivent être évalués lorsqu'on examine la qualité des plaques de laine minérale :

•Densité : Plus la laine minérale est épaisse, meilleure est la protection qu'elle offre, car elle maîtrise les blessures thermiques et l'absorption du son. De telles dalles en laine minérale doivent avoir une densité minimale de 150 kg/m3.

• Composition : Il est important de confirmer que le matériau ne contient aucun ingrédient dangereux, surtout dans le cas de la laine minérale.

• Fabrication Normes : Il est important que le produit soit conforme aux normes ou certifications applicables de l'industrie, y compris ISO et ASTM.

La Surface de la Laine Minérale

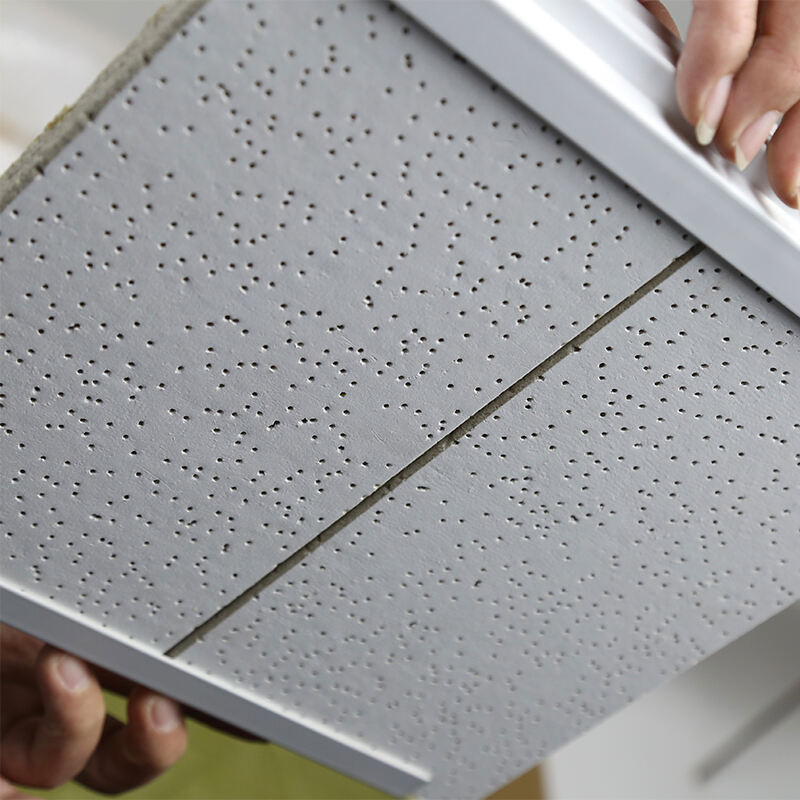

À l'étape de composition de la plaque de laine minérale, il y a une tentative de réaliser un traitement de surface. Les fabricants courants effectuent un polissage de la surface de la plaque de laine minérale et un traitement de pulvérisation pour mettre en avant les qualités du panneau de laine minérale. La principale raison du fini des surfaces et bords des plaques de laine minérale n'est pas seulement esthétique, mais essentielle dans des domaines tels que la définition du niveau sonore ou le contrôle de la rétention d'humidité. La surface doit être plate, propre et exempte de défauts.

Voici les points à prendre en compte lors de la réalisation de cette activité :

• Lisse : Une bonne surface lisse indique un bon savoir-faire en fabrication et les peintures adhèrent très bien lorsque vous devez personnaliser les carreaux.

• Revêtement et Texture : Une couche protectrice est présente sur de nombreux carreaux de qualité, augmentant leur durée de vie. Les surfaces modifiées peuvent améliorer l'absorption du son mais doivent être homogènes, sans écaillures ni rayures.

• Cohérence des Couleurs : Étant donné que les carreaux de plafond sont ajustés les uns contre les autres avec peu ou pas d'espace entre eux, une cohérence de couleur entre les carreaux est plaisante à l'œil. Les incohérences de couleur pourraient indiquer un stockage mal contrôlé des carreaux avant l'installation.

La Forme du Panneau en Laine Minérale

Notre panneau en laine minérale de spécification 600*600 est blanc et est conventionnellement utilisé comme un panneau plafond avec une modélisation de plafond relativement simple. De plus, un plafond en panneaux de laine minérale de haute qualité peut permettre une grande variété de modélisations. La forme et les dimensions des panneaux en laine minérale sont extrêmement importantes pour faciliter une installation parfaite et l'apparence du plafond. Les carreaux de qualité doivent avoir des dimensions uniformes précises avec des bords bien nets.

Certains facteurs de forme sont :

• Précision dimensionnelle : Le diamètre doit correspondre aux spécifications, généralement des tailles standard comme 600mm par 600mm ou 1200mm par 600mm. Les variations peuvent causer des problèmes d'installation et des interstices disgracieux.

• Style de bordure : Choisissez des carreaux avec des bords nets et propres qui conviennent au type de système de plafond à grilles à utiliser. Les bords incluent couramment le bord carré, le bord tegulaire et le bord caché. Les bords doivent être intacts et propres.

• Épaisseur : Tous les panneaux doivent être d'épaisseur standard afin d'avoir des propriétés acoustiques uniformes et une intégrité structurelle.

La Performance du Panneau de Laine Minérale

Lorsqu'il s'agit de plaques de plafond en laine minérale, il est nécessaire de prendre en compte des facteurs tels que l'acoustique, la résistance au feu, la facilité d'installation et la durabilité. L'efficacité du panneau de laine minérale est le critère le plus direct pour évaluer la qualité du panneau. La plupart des fabricants fournissent au moins un certificat supplémentaire concernant le panneau de laine minérale, qui inclura des informations telles que l'indice de caractéristiques d'absorption sonore, l'indice de séparation acoustique, l'indice de réaction au feu, l'indice de barrière à l'humidité et l'indice de performance.

Indicateurs à évaluer sont :

• Isolation Acoustique : Les panneaux en laine minérale de qualité doivent présenter une efficacité élevée en absorption de sons ou des coefficients d'absorption sonore élevés. Les coefficients typiques de réduction de bruit varient généralement entre 0,55 et 0,75.

• Résistance au feu : Vérifiez la classe de résistance au feu des carreaux, cela est crucial car cela indique dans quelle mesure les carreaux contiendront la propagation du feu. Il faut rechercher au minimum la Classe A.

• Isolation thermique : Une bonne isolation thermique peut également aider à améliorer l'efficacité énergétique des bâtiments car elle réduit le flux de chaleur à travers les murs.

• Résistance à l'humidité et à l'affaissement : La performance en présence d'humidité et la résistance à l'affaissement sont très importantes, surtout dans les régions humides. De bons carreaux minéraux de plafond ne doivent ni s'affaisser ni se déformer après plusieurs années d'utilisation.

• Facilité d'entretien : Il est toujours préférable que tout type de carreau soit en un matériau facile à nettoyer. Les carreaux de plafond peuvent être améliorés avec des finitions de surface résistantes aux taches et aux rayures.

Ces facteurs vous permettent de choisir de très bons carreaux minéraux de plafond de haute qualité qui performeront, auront une belle apparence et dureront longtemps dans vos projets. Le temps investi pour évaluer ces facteurs pour une conception de plafond donnée contribuera à obtenir un plafond holistique répondant aux exigences acoustiques, de résistance au feu et de design.

EN

EN