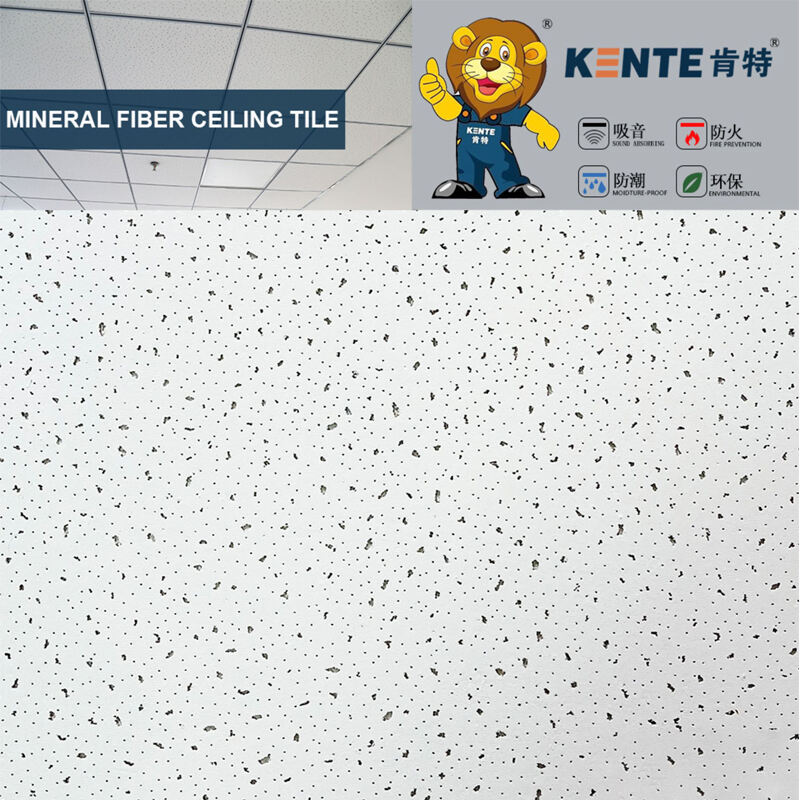

Acoustic mineral fiber board is a common sound-insulation and fireproof material widely seen in construction projects. It is usually a mineral fiber board that has binders and the result comes as panels this can be easily installed. This comprehensive guide will include the pros and cons of using an acoustic mineral fiber board, how to install them & maintain their performance once you get hold of some, top brands in the market space as well as DIY cost-effective strategies for utilizing these boards included here also are ideal thicknesses/densities to use based on your specific needs.

There are many advantages of using acoustic mineral fiber board in construction projects. The foremost advantage of GRG is sound insulation as it absorbs and reduces noise levels significantly in a room. This is great for commercial buildings, apartments and or office areas where noise reduction is a major concern. It is also fire retardant, which makes it appropriate for places necessitating a certain level of fire prevention. But the installation and maintenance for acoustic mineral fiber board are easier. Due to its versatility and affordability, it is one of the first choices in most construction works.

However acoustic mineral fiber board cannot bear the humidity so that there are some adverse aspects of it. As such, it can degrade very rapidly with water or moisture. It is important to seal the board properly if you are installing this type of board in an area where moisture tends to get into. However, it may not appeal to the eye as much a lot of materials. Today, however, technological advancement has allowed acoustic mineral fiber boards that are produced in a variety of colors and finishes to match most interior decor themes. However, even amid these downfalls the advantages of acoustic mineral fiber board are very much more than that of disadvantages.

Small Acoustic Mineral Fiber Board in Home or Office - how to install and maintain it

Acoustic mineral fiber board installing its process in fact is a relatively simple and clear. Before soundproofing, perform some tests in the room and see how thick and dense should be your set up so that it has at least an acceptable level of isolation. Identify the ceiling joists or wall studs where you are going to install board using stud finder. After that cut board to size and put it in its place. The final layer can be adhered to, fastened by screws or nailed down. The board needs to be checked for moisture or damage frequently after installation. Effective maintenance - Regular cleaning and inspections to optimize the board longevity and efficiency for sound insulation as well as fire resistance.

The existence of all the installations means that has made a for considerable reliance on maintenance well and regular cleaning to ensure its best also have long-lasting performance. Keep dust away: Vacuum or sweep the board regularly to ensure dirt and debris does not gather on its surface. Clean your board with a mild detergent and soft cloth to remove any marks or stains. Adhere to best practices in maintenance and you can help the board live a longer life whilst performing at its maximum with regards to sound insulation, fire resistance etc.

Different brands of acoustic mineral fiber board are available in the market, all having their distinctive qualities. Depending on your performance criteria for sound insulation requirements or fire resistance, with the help of ENVIRO LITE Magnesium Oxide Board is a correct solution; also in strict budget.Note The best brands are Armstrong, USG, Rockwool and Owens Corning. These brands provide excellent acoustic products that have all the properties of being a true-blue commercial/residential/industrial product. It is only natural that when it comes to your construction projects you would want sound insulation and fire protection from a renowned brand, ensuring not simply longevity but also effective solutions.

Inexpensive Ways to Fit Acoustic Mineral Fiber Board In Your Ceiling Or Partitions

Mineral wool board is a good choice for the sound insulation and fire resistance of building construction. Materials - often more inexpensive than drywall or plaster Acoustic mineral fiber board is often used to increase noise control and sound absorption. One of the most inexpensive ways to use acoustic mineral fiber board is in laiyers with other materials, such as drywall for optimum combination properties. Strategic design and integration of materials can dull noise pollution while meeting stricter fire resistance standards without blowing your budget.

Enter your text here...How to Select the Specific Thickness and Density of Acoustic Mineral Fiber Board

Another important factor in determining the performance of acoustic mineral fiber board is its thickness and density. The strong the density, beneficial for sound proofing and fire resistance properties The room size, ceiling height of the surrounding area and noise level will dictate how thick you need to go. Type 1 Primer - Density: Recommended for general use at a minimum to be 1.5 pounds per cubic foot, thickness of two inches While you should definitely ask our experts to find out what thickness and density will work best for your needs. As long as you have a deep understanding of the selection requirements for thickness and density, then at least acoustical mineral wool board can be used to meet your needs in terms of sound insulation effect and fire resistance.

In general, the acoustic mineral fiber board is a very good implementation in sound insulation and fire protection construction projects. Its advantages are quieting, affordable and easy to install. Even so, they do not perform as well if installed and maintained incorrectly. When choosing a surface-mounted acoustic mineral wool board, it is necessary to select the thickness and density according to your actual situation; after all, you get what you pay for. Choosing well-known high-quality brands can also choose sound insulation performance or fire resistance better products okay! This comprehensive guide will show you how to effectively use acoustic mineral fiber board in all your construction projects, making it safe for both occupants and environment.

Original China, renowned manufacturer ceiling tiles made from mineral fiber has made itself a global leading company the field. With an eye on quality and innovation, our ceiling tiles recognized for their longevity acoustical characteristics, as well as aesthetic appeal. Serving customers acoustic mineral fiber board, we believe providing top-quality products that satisfy the various needs of customers.

are delighted to offer our customers exclusive, personal service that allows them print their logos on acoustic mineral fiber board no cost. This exclusive feature lets you boost your brand's image create a lasting impression your clients.

specialize in offering high-quality transportation loading services specifically designed to acoustic mineral fiber boardthe specific needs international customers. Our team of experienced logistics experts provides comprehensive solutions to ensure the smooth and efficient movement of goods across the border. We take care of entire shipping procedure, from initial loading through delivery. We take pride in our ability deliver timely efficient, economical, and reliable services meet the needs of our clients. have the capacity and experience to deliver your goods safely and on-time, whether you're shipping small boxes large containers.

Different customers may require different thickness sizes of ceilings for installation,we can make sizes according customer's requirements for various countries.Mineral ceiling tiles made fiber thickness can be 7mm20mm, and over 12 patterns design. acoustic mineral fiber boarddesigns can be customized customers.Our new model is also designed provide a superior performance when it comes to the resistance to moisture .